■ Compact in size with a high degree of automation, HMI interface, stepping & servo motors driving, simple to operate

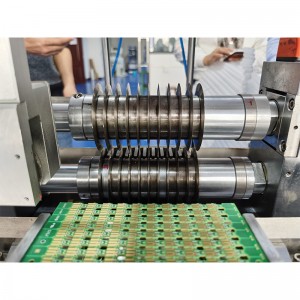

■ De-paneling at one time for PCBAs design with a cross v-scoring

■ Touch screen operation, modularized change over, easy for maintenance

■ Equipped optic sensors inside to ensure human safe

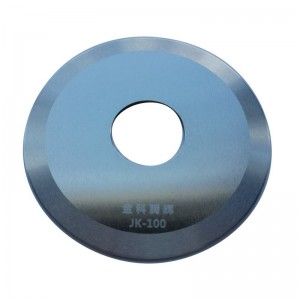

■ Unique & patent blade design with longer life-span and high accuracy cutting

■ Multi-blades design, minimized mechanical stress on SMT components, avoiding to make creaks on solder joints and broken the sensitive components

■ Standard SMEMA communication port, connect to a PCBA loader and unloader, it can be a fully automatic inline machine

■ Vacuum dust cleaner is selectable

■ CE is available

■ FOC. Sample test

If you are interested in our products, please email to Sales@jinke-tech.com

|

Model |

VCUT860INL |

|

Name |

Automatic V-Cutting Machine |

|

Size of the 1st blade module |

ϕ80mm×12mm×3mm @ 2~3pcs |

|

Size of the 2nd blade module |

ϕ80mm×12 mm×3mm -Customizable |

|

Size of Bottom straight blade |

L356*45*3mm |

|

Blade material |

Special DIE STEEL |

|

Blade brand |

Std: China-made, CAB (optional) |

|

Blade lifespan |

Std:1million times; CAB: 2 million times |

|

PCB thickness |

0.5-3.0 mm |

|

PCB Size (L/W mm) |

Min.5/5-Max.350/300 |

|

Driven mode |

Stepping motor, Servo motor(optional) |

|

Cutting speed |

Range 300mm-500mm/s |

|

Controlling system |

PLC + HMI |

|

Recipes |

100 Groups |

|

Power supply |

1 phase 220V 50hz |

|

Air supply |

4~6kgf |

|

Weight |

350kg |

|

Footprint L/W/H |

Approx. 1360 mm×800mm×1100mm |